CEM Readymix Concrete Ltd. produces and supplies high quality ready mix concrete for residential, commercial, and infrastructure projects. Each batch is created through an automated TEKA (Germany) batching system, ensuring consistent strength, reliability, and durability across all grades from M15 to M60.

Our Promise: Every cubic meter of concrete meets international standards and project specific performance requirements.

Cement

Admixtures

Sand

Water

Aggregate

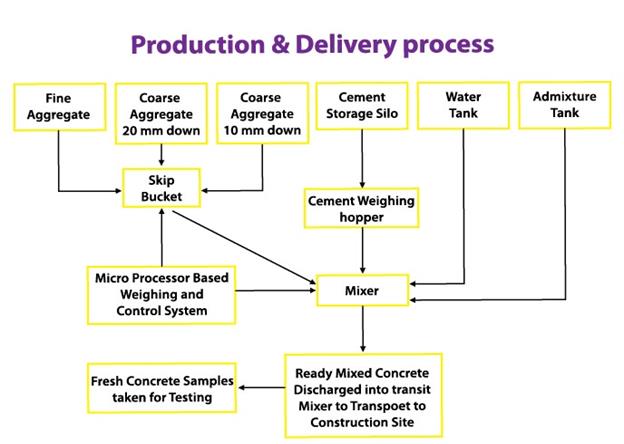

Our process ensures total control from raw material to finished concrete:

The flow chart illustrates this fully automated process from material input to final delivery

Workability Test of CEM Readymix

Use of CEM Readymix Concrete

Flow Chart of Production and Delivery process

In present operation the following are the machinery supports-

CEM is the first in Chattogram to introduce the Putzmeister BSA 1410 D FEH (Germany) with a VOLVO Penta engine, offering: